快速送货

所有订单

150,000 种产品

品种齐全

超过14年

信任和经验

ANSI、ISO 认证

满意保证

35 Roller Chain

#35 Roller Chain

The ANSI 35 roller chain is the second smallest size in the ANSI series, designed according to the precise standards set by the American National Standards Institute (ANSI) B29.1. This design allows the 35 chains to be compatible with standard 35 sprockets from various manufacturers.

We offer a wide range of 35 roller chains including stainless steel, nickel-plated, and multi-strand options, as well as custom attachment styles. For more information or to request a quote, please contact our customer support team who will be glad to assist you.

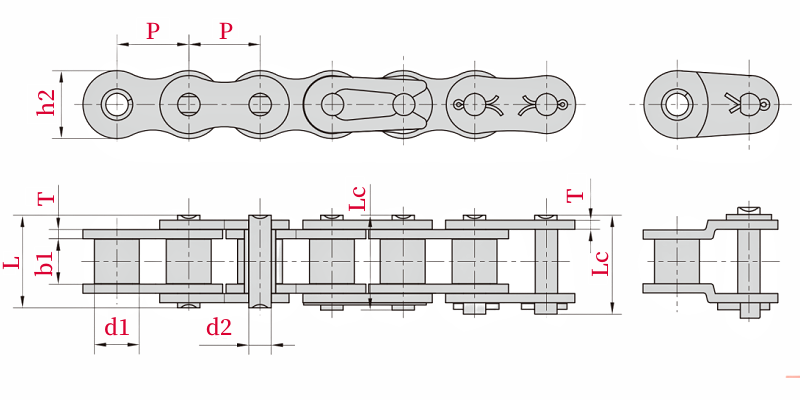

35 Roller Chain Dimension

|

Pitch

|

Roller diameter

|

Roller width

|

Pin diameter | Pin length |

Plate depth

|

Plate thickness | Weight |

|

P

|

d1

|

b1

|

d2 | L |

h2

|

T | per/ft |

|

0.375"

|

0.200"

|

0.188"

|

0.141" | 0.472" |

0.354"

|

0.049" | 0.21 lbs |

35 Roller Chain Specs

We offer a variety of RS35 chains to address specific needs. Here are some 35 roller chains with different specifications designed to address challenges in 35 roller chain applications. Our ANSI 35 roller chain is made from high-quality steel components and features heat-treated and shot-peened components.

35 Roller Chain Accessories

#35 roller chain attachments are essential components designed to enhance the functionality and adaptability of standard 35 roller chains. ANSI 35 roller chains with attachments are commonly used in conveyors, packaging, and agricultural machinery.

35 Chain Connecting Links

35 roller chain connecting link, also known as a #35 master link, is a removable component used to join or disconnect sections of a roller chain. It allows quick and easy maintenance, making the roller chain assemble or disassemble in machinery.

35 roller chain breakers are designed to cut and break roller chains efficiently. It simplifies removing or resizing chains by separating the links without damaging them.

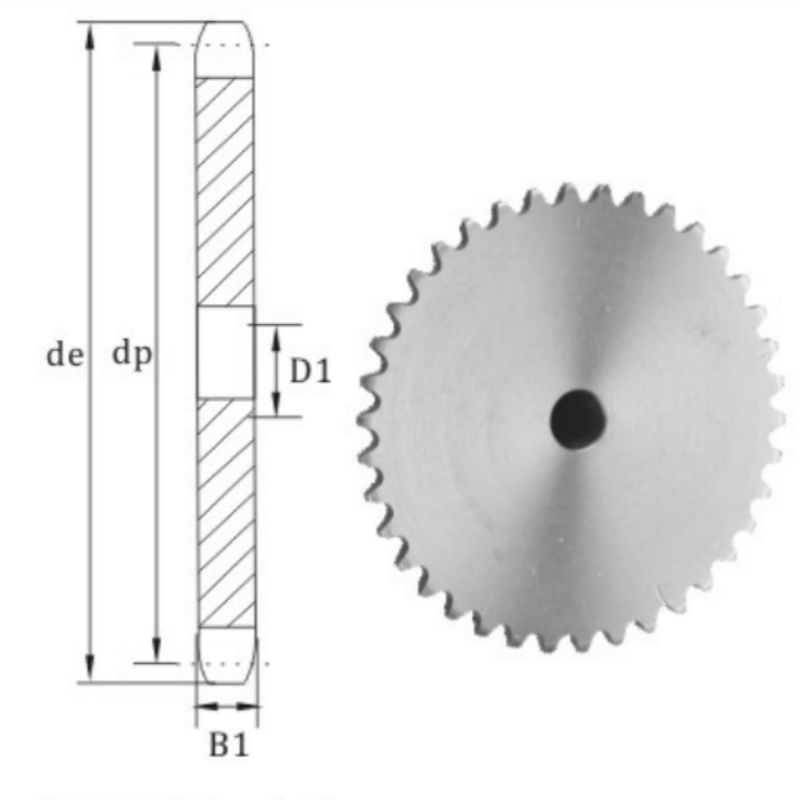

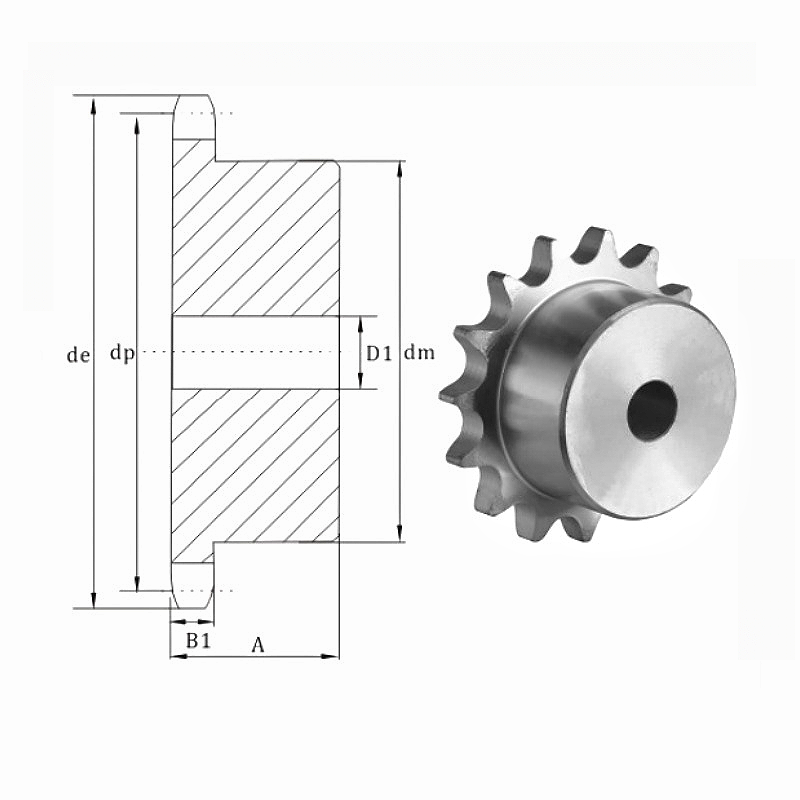

ANSI 40 roller chain sprockets are engaged with size 35 roller chains. We have a complete selection of 35 chain sprockets ranging from A-plate, B-hub, taper-bushed, plain bore sprocket, and finished bore sprocket configurations.

35 Roller Chain Sprocket

35A Sprockets Dimensions

35B Sprockets Dimensions

35 Roller Chain Solution

We manufacture 35 roller chains using high-quality materials and offer various material options to meet special requirements and applications.

If you don't find a solution that meets your requirements, please contact us for customized options.

Carbon Steel 35 Roller Chain

Our carbon steel #35 roller chain boasts high strength and wear resistance, making it ideal for typical operating environments. ANSI 35 roller chain finds applications in various industries, including general industrial and agricultural machinery.

Stainless Steel 35 Roller Chain

35 Stainless steel roller chains are characterized by their high resistance to corrosion, making them well-suited for use in demanding environments. ANSI 35SS roller chain finds applications across various industries including pharmaceuticals, chemicals, and marine equipment, where durability and reliability are needed.

Nickel Plated 35 Roller Chain

In humid and mildly corrosive environments, Nickel-plated #35 roller chains showcase their resistance to rust and corrosion, rendering them suitable. The 35NP roller chains are mostly employed in food processing equipment and outdoor machinery.

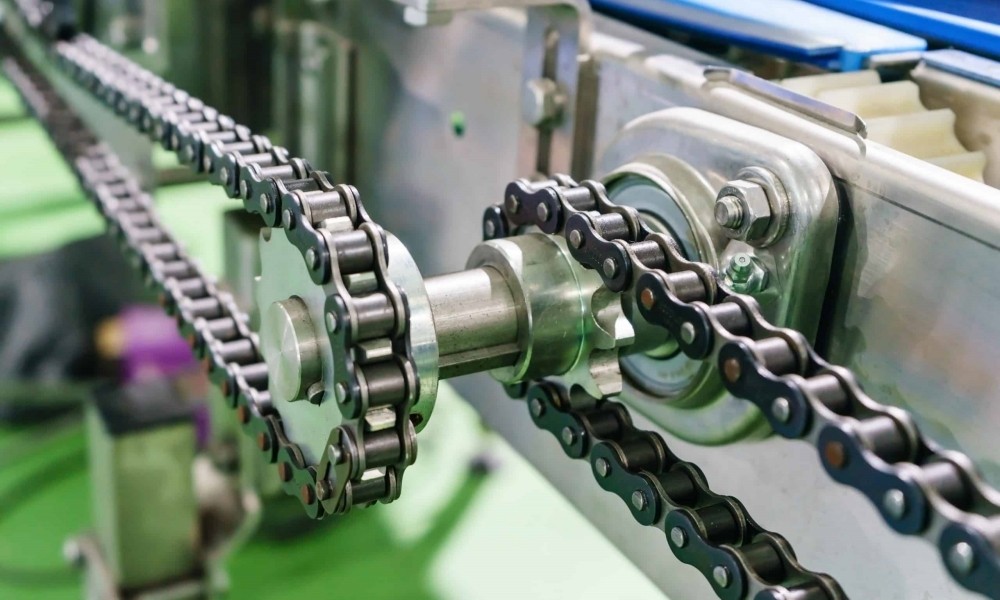

35 Roller Chain Application

ANSI #35 roller chain is widely used in many industries and has become the main chain size for most applications. Each component of our #35 chain is precisely manufactured professionally heat-treated and shot-peened for optimal performance. Keep in mind that the standard carbon steel 35 chain is designed to operate in temperatures from 15°F to 140°F, with a heat-treated hardness range of HRC 45-55. For any situations outside this range, please contact us for a solution.

Conveyor Systems: Used in various types of conveyor systems to move materials and products efficiently.

Agricultural Machinery: Employed in equipment such as harvesters, tractors, and planters for transmitting power.

Industrial Machinery: Utilized in machines like packaging equipment, printing presses, and textile machinery for power transmission and operational functions.

Food Processing Equipment: Used in food processing machinery due to their availability in corrosion-resistant materials like stainless steel or with special coatings.

Mining Equipment: Used in mining operations for machinery that requires durable and robust power transmission solutions.

Material Handling: Essential in systems like palletizers and depalletizers for handling and moving materials in warehouses and distribution centers.

Elevators and Lifts: Incorporated into the mechanisms of elevators and lifting equipment to ensure smooth and reliable operation.

35 Roller Chain Resource

0个结果

视图橱窗

CTS®'s Commitment

Enhanced Durability:

Our 35 Roller Chain is crafted to handle exceptional strength, ensuring longevity and reliability in your operations.

Smooth Performance:

Designed to minimize friction and maximize efficiency.

Versatile Applications:

Suitable for a wide range of applications, providing flexibility and adaptability.

Reduced Downtime:

Decreased maintenance due to robust construction and dependable performance.

Quality Assurance:

Our #35 Chain undergoes rigorous testing to meet ANSI standards, guaranteeing superior performance.

Professional Roller Chain supplier

CTS® Roller Chain is a trustworthy provider due to its commitment to quality, expertise, and customer service. With many years of extensive experience, CTS® offers high-quality products and assistance from a team of professional technicians. Whether you need standard roller chains, specialty chains, or roller chain sprockets, CTS® ensures durable and dependable solutions customized to your project needs.